Kilma Futura: radiant systems with low thermal inertia

Generally of low thickness, they are often implemented as 'dry systems'. They have the capacity to heat up within minutes, and are also suitable for discontinuous use. Thanks to their characteristics, they are perfect for renovations and for the construction of new homes with a high thermal efficiency envelope

No cement screed required

At full operation in 43 minutes

Minimum total thickness, even less than 3 cm

The revolutionary system with minimal overall thickness and maximum energy efficiency ideal for renovations and new builds.

The advantages of the system

No cement screed is needed Low thermal inertia: heats up in a few minutes Great savings Maximum comfort Floor, wall, ceiling installation For heating and cooling systems Total thickness less than 3 cm Quick and easy to install Ideal for restorations and new homes with high energy efficiencyDoes not require screed

or supporting layers under the finished floor!

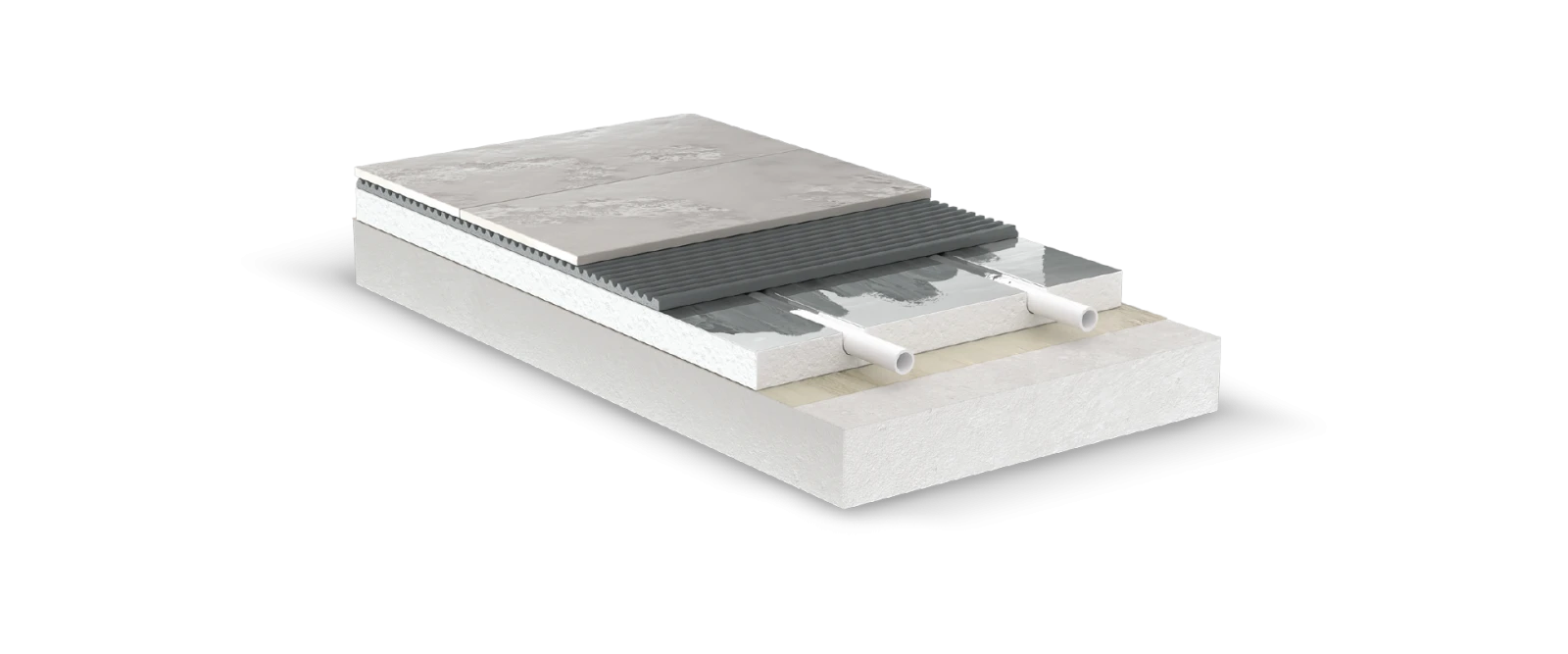

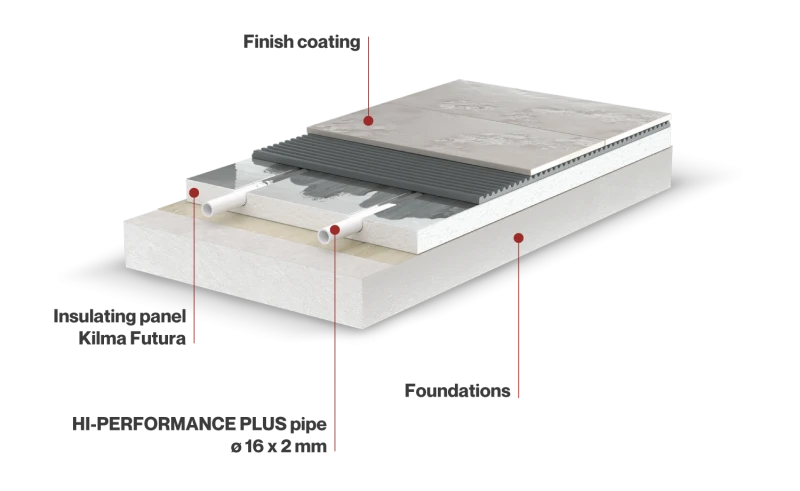

Kilma Futura is a revolutionary radiant system, without screed and characterised by its extremely small overall size, which allows for finished underfloor heating and cooling systems in less than 3 cm.

A unique characteristic of Kilma Futura is the possibility of laying the floor directly on the insulating panel, without having to provide a supporting and load-distributing layer such as metal plates, fibreglass panels, sheathing, netting, etc. This greatly simplifies and speeds up the installation work, as well as considerably reducing costs and critical implementation issues.

Furthermore, when building a system with Kilma Futura, only one type of panel is used for the entire site, without having to distinguish between panels for ends, intermediate, bends, etc.

Each panel is already equipped with pre-moulded tracks and bends to accommodate the pipework.

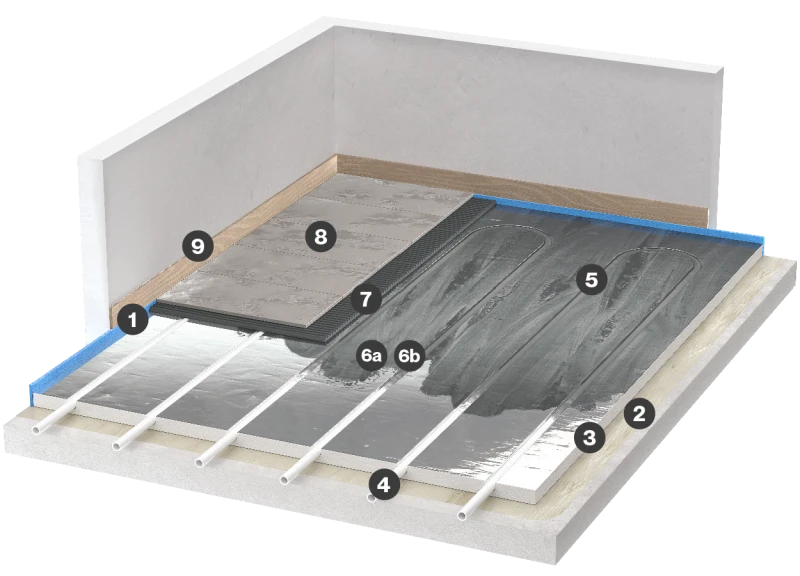

Ceramich finish

1 Perimeter expansion joint

2 Glue for fixing the panel to the substrate

3 Kilma Futura Panel

4 HI-PERFORMANCE PLUS PE-RT PIPE Ø16x2 mm

5 If necessary, aluminised tape to block the pipe on the bends (qty approx. 1 m/m²)

6a Protection epoxy primer (e.g. PRIMER MF RBM by Mapei)

6b Superior glue gripping primer (e.g. ECO PRIM T by Mapei - not supplied)

7 Glue for tiles (not supplied)

8 Tiles (minimum dim. 25x25 cm or in alternative 15x30 cm strips)

9 Skirting board

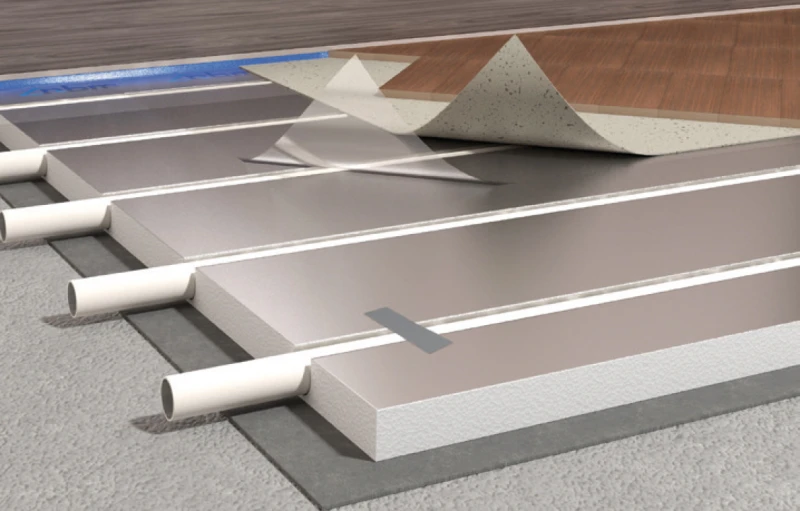

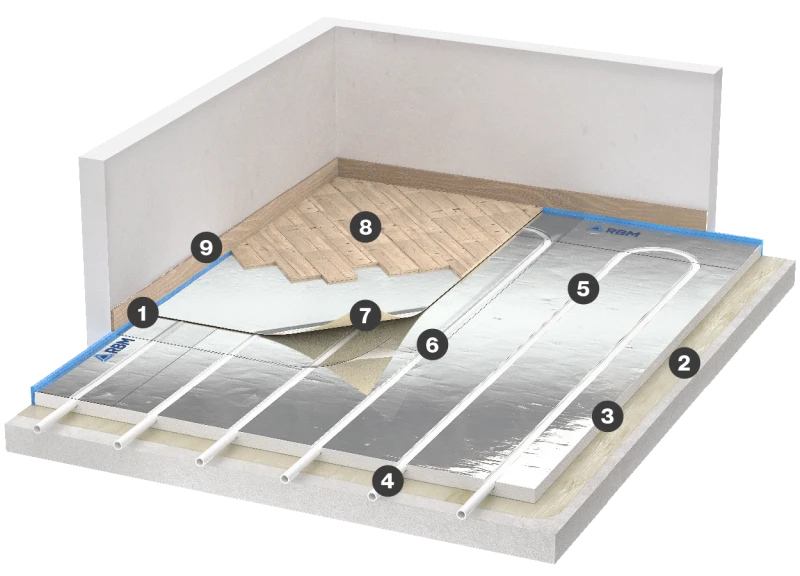

Parquet finish (Type 1 floating parquet)

1 Perimeter expansion joint

2 Glue for fixing the panel to the substrate

3 Kilma Futura panel

4 HI-PERFORMANCE PLUS PE-RT PIPE Ø16x2 mm

5 If necessary, aluminised tape to block the pipe on the bends (qty approx. 1 m/m²)

6 PE protective sheet

7 Specific support mat (e.g. ISOLMANT TOP by Isolmant - not supplied)

8 Floating parquet placed resting on the underlying surface

9 Skirting board

Parquet finish (Type 2 glued parquet)

1 Perimeter expansion joint

2 Glue for fixing the panel to the substrate

3 Kilma Futura panel

4 HI-PERFORMANCE PLUS PE-RT PIPE Ø16x2 mm

5 If necessary, aluminised tape to block the pipe on the bends (qty approx. 1 m/m²)

6 ISOLTILE Classic or TOP INCOLLAPAVIMENTO support mat by Isolmant (not supplied)

7 Glue for parquet (not supplied)

8 Parquet

9 Skirting board

Immediate walkability!

Speeds up construction avoiding drying times of the screed

In traditional radiant systems, the cement screed always needs a drying and curing time which, although it varies depending on the thickness and type of material used, is generally never less than 3 to 4 weeks. In addition, at the end of this period, at least another week must elapse in order to be able to carry out the 'first start-up' test as required by EN 1264-4. For the entire time the screed is laid, the construction site is not accessible internally, which increases the time and cost of the work. In addition to this, the laying of the screed entails the presence of several operators throughout the entire pouring period, which significantly increases the risk of the pipes being punctured. Kilma Futura avoids all this.

The absence of a screed, in addition to drastically reducing construction time, allows the plumber to easily control all phases of the construction site, avoiding the intervention of third parties and significantly facilitating all testing operations required by the technical standard.

A system that immediately reaches full operation avoids stealing heat because it is a true insulation panel

Kilma Futura is a radiant system that reaches full operation extremely quickly. When compared to a conventional system, it can be seen that Kilma Futura is up and running in less than 45 minutes, i.e. 8 times faster!

This peculiarity makes Kilma Futura the ideal solution for holiday homes, spaces that are used occasionally and, more generally, for all homes that remain empty for many hours of the day.

Thanks to Kilma Futura, it is now possible to achieve the excellent level of comfort typical of a low-temperature radiant system, without necessarily having to keep the system running continuously throughout the day. The result is a considerable money savings and improved quality of life.

The heart of the Kilma Futura system is the insulation panel. Many radiant systems with low thermal inertia, as well as many 'dry' systems, have pipe containment layers made of materials that do not oppose the minimum thermal insulation to the downward diffusion of heat such as concrete, fibre cement and the like.